-

SHIZUOKA SEIKI

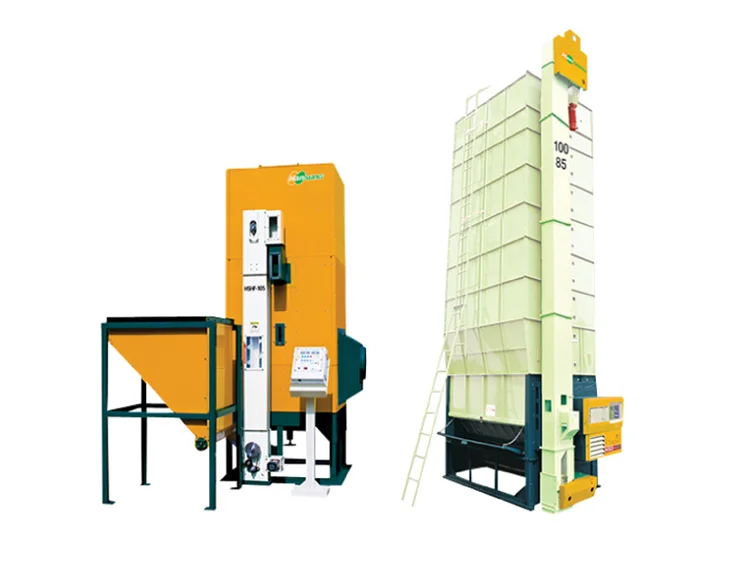

HSD-MD SERIES

This Shizuoka Seiki grain dryer is a grain processing equipment that offers automatic drying capabilities, precisely meeting target moisture levels for optimal grain quality.

Farm Machinery

Grain Processing

About Grain Dryer

A Grain Dryer is an essential grain equipment especially crucial in regions facing unpredictable weather. This machine aims to lower the moisture levels of various grains, including corn, wheat, rice, and barley, to ensure they are safe for storage and to avoid spoilage and loss.

Grain Dryers operate by blowing hot air through damp grains to remove surplus moisture. Operators can achieve this through various methods such as continuous flow, moving grains continuously through the dryer, and batch systems, drying grains in fixed intervals. Effective drying depends on precise control over temperature and airflow, crucial for even drying and preventing grain damage.

Advanced features like automated temperature and moisture controls equip modern Grain Dryers. These enhancements enable exact drying, suitable for different grain types and moisture conditions, crucial for preserving grain quality and reducing energy use.

Drying is not only vital for grain preservation but also for maintaining grain quality. Grains dried correctly are at a lower risk of fungal and mycotoxin contamination, and significant health risks. Moreover, dry grains are processed and handled more efficiently, improving product quality and market value.

Grain Dryers preserve the quality, safety, and economic value of harvested grains. They provide a controlled drying environment, essential for global food security and agricultural supply chain efficiency. Their effective moisture reduction capability marks them as key in modern farming methods.

25 Years of Service in Agricultural Industry