-

GRAINPRO

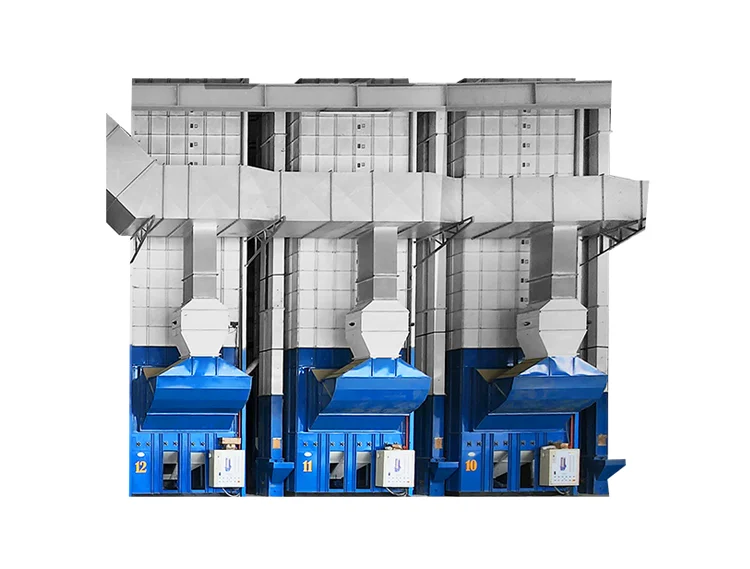

OGD-SERIES

This Grainpro grain dryer is a grain processing equipment with a double cyclonic effect that creates an air/husk vortex, ensuring complete smoke-free combustion.

Farm Machinery

Grain Processing

About Grain Dryer

A grain dryer is primarily used to reduce moisture in grains like corn, wheat, rice, and barley. This step prevents spoilage and maintains the grains' quality, longevity, and readiness for storage and further processing.

This grain equipment operates by pushing hot air through damp grains to evaporate extra moisture. This can happen in a continuous flow, with grains moving through the dryer, or in a batch system, where grains stay still for a while. Controlling the temperature and airflow is crucial to dry grains evenly and softly, keeping their quality and avoiding heat damage.

Designers have made modern grain dryer with efficiency in mind. They come with automated moisture sensors and temperature controls for precise drying. This adjusts to various grain types and moisture levels, improving energy efficiency and cutting down on costs.

The benefits of using a grain dryer go beyond grain preservation. Drying grains properly reduces the chance of fungal growth and mycotoxin production, securing the food supply's safety. Moreover, dry grains handle and process better, keeping their quality and value.

Grain dryers are especially important in areas with unpredictable weather or high humidity, where air-drying grains is hard. Their impact on the agriculture industry is significant, ensuring the quality, safety, and economic value of crops. By providing the best drying conditions, this machine is essential for global food security and the smooth functioning of the agricultural supply chain.

25 Years of Service in Agricultural Industry